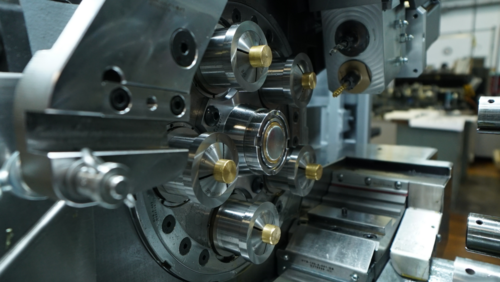

A multi-spindle machine, also known as an automatic lathe machine or screw machine, is a type of lathe with more than one working spindle. Each spindle holds its own individual workpiece, with one or more opposing cutting tools to complete various machining operations. These spindles are contained inside of a revolving drum (see example below), that indexes each spindle around to the multiple working positions on the machine. These machines are commonly used for the manufacture of high-volume precision parts in a variety of industries.

Most machines classified as a multi-spindle automatic lathe contain 5, 6, or 8 spindles. Each multi-spindle machine has a corresponding tooling position that directly correlates with the number of spindles the machine has. The opposing tools in each position continuously perform the same operation on the workpiece throughout the work cycle, as the revolving drum indexes following the successful completion of the previous operation. Each index of the revolving drum (head) will yield a complete workpiece.

Producing multiple workpieces at once gives multi-spindle automatic lathes a distinct advantage over their single-spindle counterparts. These machines can produce precision parts with extremely fast cycle times and high-efficiency rates, making them commonplace in many industries. Such as; automotive, aerospace, medical, defense, electronics, and many others.

Multi Spindle Lathe

A lathe is a machine traditionally used to produce round components. The material, usually in blank or bar stock form, is held in a collet or multi-jaw chuck to secure the work piece. The material is then spun on its axis allowing for machining operations to be completed, resulting in a finished work piece. Common lathe operations include single-point turning, single-point threading, drilling, reaming, boring, and more.

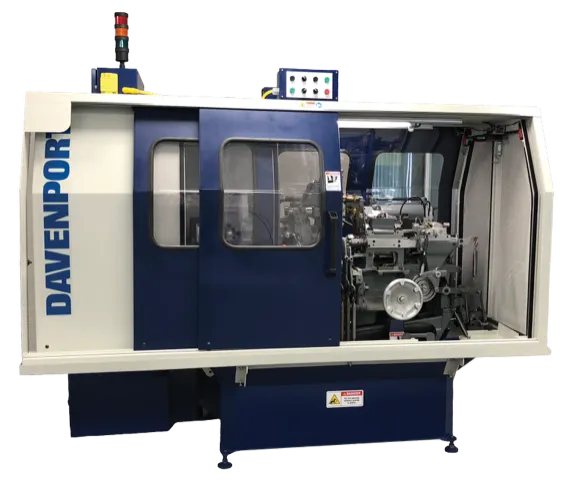

For mass production, multi-spindle automatic lathe machining capabilities are preferred. This is due to the fact that multi-spindle machines can yield, in many cases, production levels 4 to 6 times higher than a single spindle machine. Machines like a Davenport can perform the same operations as a single spindle lathe, but in a fraction of the time.

Davenport Multi Spindle Automatic Lathe

Davenport Multi-Spindle automatic lathes contain 5 working spindles for the completion of precision parts. Davenport’s main distinction is its revolving head index time. As explained above, a completed work piece is dropped off the machine with each index of the machines revolving head. Davenport machines boast the fastest revolving head index speeds in the industry. This gives users the benefit of producing faster cycle times than any multi-spindle automatic lathe machine available on the market today.

Davenport offers a full line-up of multi-spindle automatic lathes suited for the toughest high volume production challenges and machining capabilities.

The Davenport Model B has been proven in the precision parts industry for over a century. Still to this day the fastest multi-spindle automatic lathe machine in the world, the Model B can handle the largest production requirements.

The Davenport Hybrid Machine is the most advanced machine offered by Davenport. CNC controls, and superior rigidity allow the Hybrid to tackle the toughest alloys and manufacturing demands. Superior capabilities and automatic bar loading make the Hybrid Machine the perfect fit for todays high volume production environment.

See Davenports full line of multi-spindle machines here.

The Difference Between Single Spindle And Multi Spindle Automatic Lathes

Single-spindle lathes and multi-spindle lathes differ primarily in the number of operations that can be performed and their production efficiency.

1. Number of Spindles

- Single-spindle lathes have only one spindle, which means they can process one workpiece at a time.

- Multi-spindle automatic lathes have multiple spindles (typically two or more), allowing them to process multiple workpieces or perform multiple operations on a spindle workpiece, at the same time

2. Productivity

- Single-spindle lathes are suitable for low to medium volume production. They are ideal for small batch lot runs.

- Multi-spindle automatic lathes are designed for high volume production. With the ability to process multiple precision parts and operations at the same time, they offer significantly higher throughput and productivity.

3. Flexibility

- Single spindle lathes are suitable for a wide range of machining tasks and precision parts sizes in small volume.

- Multi-spindle automatic lathes excel in high-volume, repetitive production in a fast cycle time, and where efficiency and throughput are paramount.

Single-spindle lathes are suitable for small to medium production runs, while multi-spindle lathes are geared toward high volume precision part production where maximizing productivity and efficiency are essential. The choice between them depends on production volume, complexity of parts, and budget considerations.

Contact Davenport

If you have any questions or would like to request a quote, feel free to contact us directly!References

- http://www.metramh.com/en/160303/NewsaboutCNCMultiSpindlemachinesautomaticlathesandscrewmachines/CNCAUTOMATICLATHESorCNCMULTISPINDLELATHES.htm

- http://www.gewinc.com/single-spindle-multi-spindle-screw-machining-illiniois.html

- http://old.bgk.uni-obuda.hu/ggyt/targyak/seged/baggt23nec/book_05.pdf

- http://www.mmsonline.com/articles/cnc-multispindles-are-they-for-you

- http://todaysmachiningworld.com/magazine/multi-axis-turning-machines-versus-single-spindle-screw-machines/

- https://www.scribd.com/doc/41406332/Single-Multiple-Spindle-Automatic-Lathe

- https://en.wikipedia.org/wiki/Automatic_lathe

- http://www.decomag.ch/pdf/2006/tornos-dmag-200602037-rpv-single-or-multi-spindle-en.pdf

- https://www.tornos.com/en/content/multispindle

- https://en.wikipedia.org/wiki/Spindle_(tool)

- http://www.sotechcorp.com/MSH/msh.php

- https://www.kingsang.com.tw/eg/product_e1.html

- https://www.unb.ca/fredericton/engineering/depts/mechanical/_resources/pdf/sop/drill-press.pdf

- http://www.ijritcc.org/download/conferences/ICEMTE_2017/Track_3_(MECH)/1490082526_21-03-2017.pdf

- http://www.ijtrd.com/papers/IJTRD3894.pdf

- http://www.drill-hq.com/2011/09/the-advantage-of-multi-spindle-heads-explained/

- http://www.iosrjournals.org/iosr-jmce/papers/sicete(mech)-volume1/11.pdf

- http://www.productionmachining.com/zones/screw-machines-multi-spindle