Table of Contents

ToggleBasics of Multi-Spindle Screw Machines

A multi-spindle screw machine is a type of lathe with more than one working spindle. Each spindle holds its own individual workpiece, with one or more opposing cutting tools to complete various machining operations. These spindles are contained inside of a revolving drum (see example below), that indexes each spindle around to the multiple working positions on the machine. These machines are commonly used for the manufacture of high-volume components in a variety of industries.

Most machines classified as multi-spindle lathes contain 5, 6, or 8 spindles. Each one has a corresponding tooling position that directly correlates with the number of spindles the machine has. The opposing tools in each position continuously perform the same operation on the workpiece throughout the work cycle, as the revolving drum indexes following the successful completion of the previous operation. Each index of the revolving drum (head) will yield a complete workpiece.

Producing multiple workpieces at once gives multi-spindle lathes a distinct advantage over their single-spindle counterparts. These machines can produce parts with extremely fast cycle times and high-efficiency rates, making them commonplace in many industries. Such as; automotive, aerospace, medical, defense, electronics, and many others.

Davenport Machine’s multi-spindle screw machine capabilities include:

- Forming

- Back-working

- Drilling

- Reaming

- Broaching

- Cross milling

- Flat generation

- Cross drilling

- Thread rolling

- Shaving

- Swaging

- Burnishing

- Keyway milling

- Slotting

Multi-Spindle Lathe

A lathe rotates worked material on its axis to facilitate performance of operations including, single-point turning, single-point threading, drilling, reaming, boring etc… It operates by applying tools to the worked material as the lathe spins.

For mass production, multi-spindle lathes are preferred. This is due to the fact that these machines can yield, in many cases, production levels 4 to 6 times higher than a single spindle machine. Machines like a Davenport can perform the same operations as a single spindle lathe, but in a fraction of the time.

Types of Multi-Spindle Screw Machines

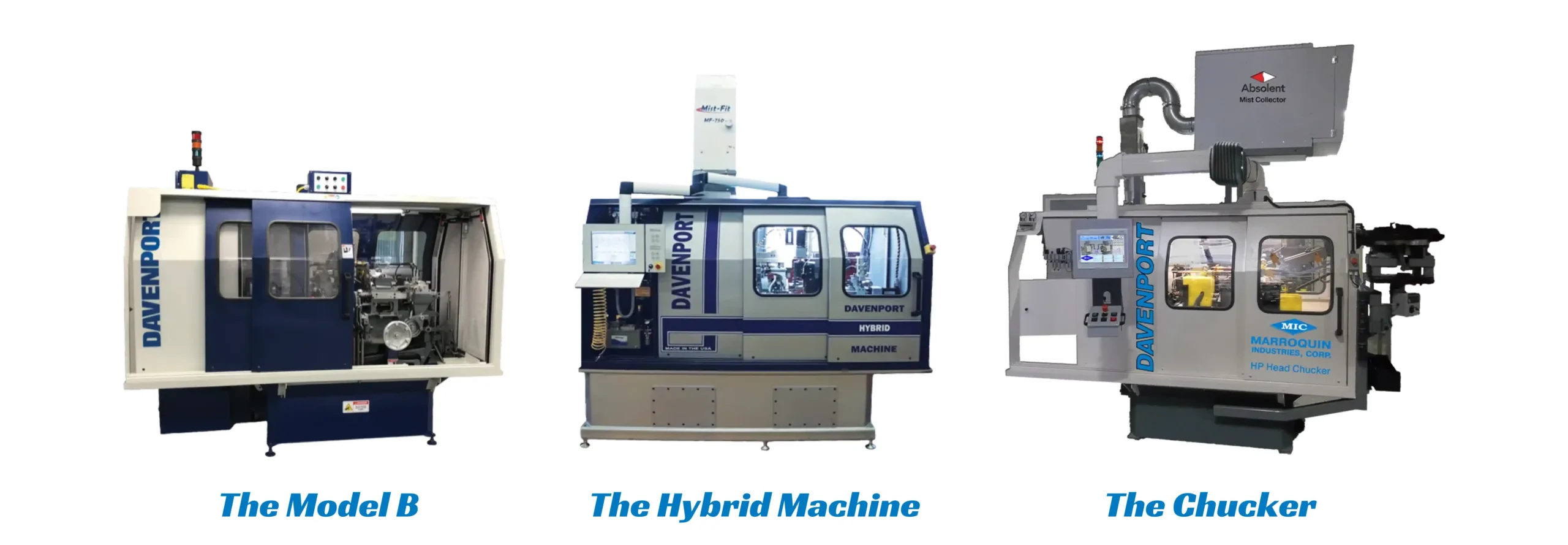

Davenport Machine’s multi-spindle screw machines deliver the most efficient production method for high-volume parts. Our selection of elite screw machines includes the Davenport Hybrid Machine, the Model B, and the Chucker.

Davenport Hybrid Machine

The Davenport Hybrid Machine is the most advanced machine offered by Davenport. CNC controls, and superior rigidity allow the Hybrid to tackle the toughest alloys and manufacturing demands. Superior capabilities and automatic bar loading make the Hybrid Machine the perfect fit for today’s high volume production environment.

Model B

Since 1900, the Model B Davenport Machine continues to be the most economical multi-spindle automatic screw machine available. The Model B offers simplified setup and minimal operating time.

Chucker

The Chucker is Davenport Machine’s five-spindle chucking machine, and is designed for medium–and high-volume secondary operation work for parts of up to 2.25-in diameter.

Improve Your Process Automation with Davenport Machine

For more than 130 years, Davenport Machine has offered multi-spindle screw machines that maximize production efficiency. To learn more about how our screw machines will improve your production line, request a quote today!