Davenport has reinvented the way remanufacturing is done.

Every step has been re-engineered and hundreds of improvements were made to the process, the enhanced specifications and tolerances. Strict quality assurance measures are put into place at every step, part, and assembly.

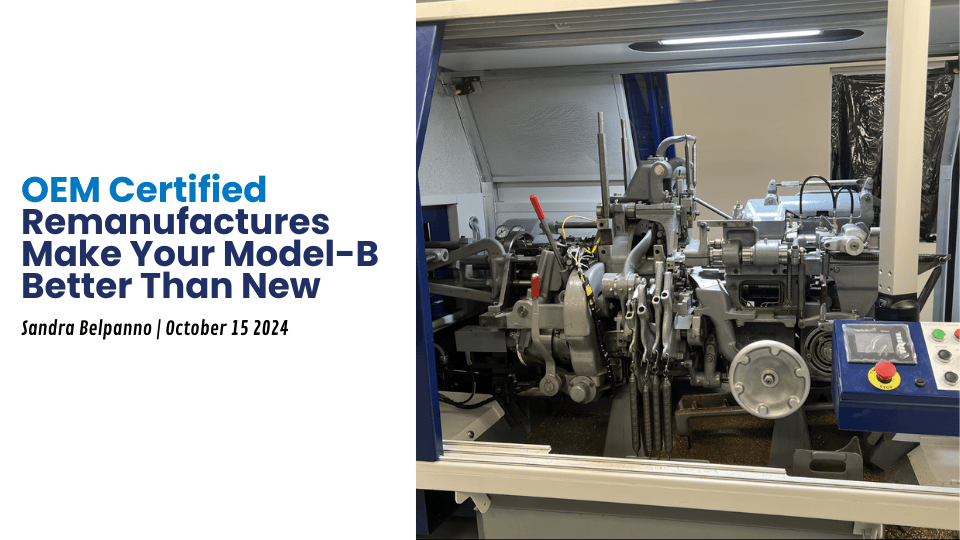

Our state-of-the-art manufacturing facilities are unmatched in the rebuilding industry. This is not your grandfather’s garage-shop rebuild. Your worn-out machine is restored to 21st century, factory-new OEM specifications, on the same equipment used to make brand new Davenports today.

When we return your machine, it's better than when it was new ... It's Davenport Remanufactured:

- 100% OEM parts, built to the highest quality standards by an ISO 9001-certified factory

- Inspected and assembled by Davenport trained technicians, with experience of over 50 years

- All remanufactured machines come with a Davenport’s “New Machine Warranty”

Remanufacturing also includes the following upgrade options:

- OEM upgrades, attachments and equipment available for your specific application

- High Precision (HP) Head upgrade available, installed by the company who developed the patented HP technology

- Sound enclosures and safety door interlocks are available to conform to OSHA and NFPA requirements

Model B Rebuilds |

|---|

Model B Remanufacture Includes NEW: |

5th Position Stationary Head Burring Attachment |

Stationary and Revolving Heads |

Inner and Outer Revolving Spindles with Bronze Bearings |

Ball Bearing Feed Tube Assemblies |

Chuck Slides |

Barrel Chucking |

1st and 2nd Position Slides |

Stationary Tool Spindles and Boxes |

Main Bearings and Bushings |

Lubrication System with Motorized Pump |

Chucker Rebuilds |

|---|

Chucker Remanufacture Includes NEW: |

Stationary and Revolving Heads |

Inner and Outer Revolving Spindles with Bronze Bearings |

Chuck Slides |

Barrel Chucking |

1st and 2nd Position Slides |

Stationary Tool Spindles and Boxes |

Main Bearings and Bushings |

Lubrication System with Motorized Pump |

Recent Related Articles

How OEM Certified Remanufacture Makes Your Model-B Better Than New

October 15, 2024

What are the Top 3 Benefits of a Davenport Machine OEM Rebuild?

September 27, 2024

Davenport Introduces New and Improved OEM Replacement Parts

December 2, 2019