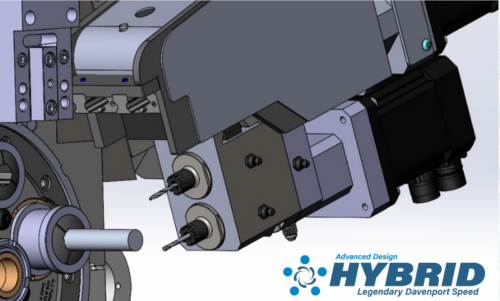

Davenport Hybrid Setup Time Reduction & Benefits

With a legacy spanning over 130 years, there is no question our company has seen tremendous change in manufacturing. In today’s ultra-competitive manufacturing world, time seems to always be of the essence. Innovative Tooling System for the Hybrid CNC Platform With this in mind our team of engineers developed a