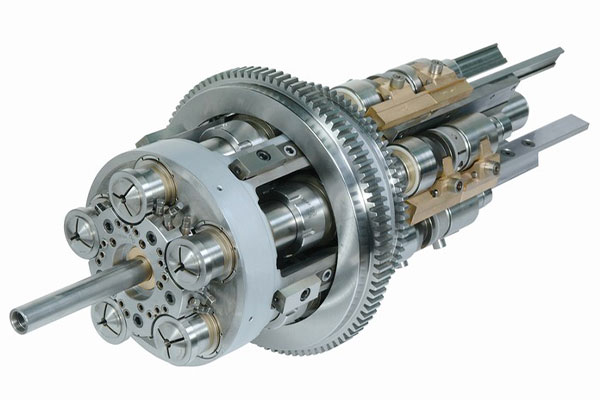

Davenport Machine introduces a new dimension of accuracy and repeatability for your Model B and Davenport HP machines: the HP Head.

The HP (High-Precision) Revolving Head is designed with ABEC 9 angular contact front and rear bearing, and precision spindles. This improves spindle runout, dimensional accuracy, and results in a longer service life than the standard 8-SA Revolving Head. HP Heads an available option for new and remanufactured Model B machines or in field retrofit.

Machine Heads

FAQs about the High-Precision Head

Get answers to some of the most commonly asked questions about the HP head, including details about accuracy, rigidity and cost information.

FEATURES |

|---|

The New Davenport HP Head Provides: |

Increased spindle rigidity |

Improved part diameter accuracy |

Improved surface finishes |

Improved part roundness |

Less part taper and deflection |

Substantially increased spindle life |

Improved spindle index repeatability |

Improved spindle run-out |

Wear resistant coating that reduces galling and increases revolving head life |

Positive pressure constant lubrication |